The Leica iCON trades solution for digital templating is particularly suitable for the creation of digital templates and covers the specific needs of stonemasons, glaziers, bathroom fitters, and marine interior professionals. With this software you create digital templates quickly and accurately. You can finish the data directly on site and forward it to the CNC machine for production.

Your advantages:

The Leica iCON iCS50 small but powerful measuring device including accessories can be carried and operated by one person. Automated processes ensure that everything is ready for use quickly and reliably.

The specially developed 'quick mount release' allows the device to be snapped to the tripod without needing to screw it on.

Automated processes such as 'auto levelling' ensure that the device is correctly set up and quickly ready for use, ensuring a high level of efficiency.

Reliable operation for indoor and outdoor use with an IP54 rating for protection against dust and water ingress.

Leica iCON trades is tailored to quickly create and process accurate digital templates from simple to complex shapes.

The handling is easy to learn and the device and software can be used immediately.

The software follows the digital templating-specific workflows and ensures a seamless data flow, from capturing 2D and 3D measurement data, to the completion of drawings on site with powerful CAD tools, and the transfer of CNC-ready files directly to production.

Simple to use

The visual measurement technology always displays the current situation and prevents anything from being forgotten.

Automated workflows also reduce measurement complexity to a minimum. The unique solution combines multiple measurement technologies to ensure precise and reliable data collection via wireless Leica vPen, laser, line or area scans.

In addition it does not matter which direction you are moving the Leica vPen. Its unique pattern is always reliably detected by the Leica iCON iCS50.

With Leica iCON trades you can capture high-precision measurement data even from hard-to-access locations. The software is easy to use.

You see the measurement results immediately as a 2D plan or 3D model on your tablet. This way you can be sure that you haven't forgotten any measuring point.

The unique wireless measuring pen Leica vPen is extremely precise. Use it to measure on any surface, even glass, by simply touching the point to be measured.

You can also measure edges without having to set up target plates. The visual-based target tracking ensures that the Leica iCON iCS50 stays connected to the Leica vPen. Automated relocation process ensures a quick and easy relocation of the device.

Create the production data directly on site with the powerful CAD tools of Leica iCON trades. Connect lines or polylines and add offsets, layers, profiles, dimensions and cut-outs, e.g. for stove, sink, water tap, sockets, holes and notches.

The digital templates created in this way are extremely accurate because they are based on the original site dimensions.

Save the DXF file for post-processing into your preferred CAD/CAM software or import it directly to the CNC machine.

You can access the data via cable, e-mail, or cloud services. Automated production processes based on precise CAD data save time, money and reduce material waste as errors are minimised.

This lowers the environmental footprint of a project.

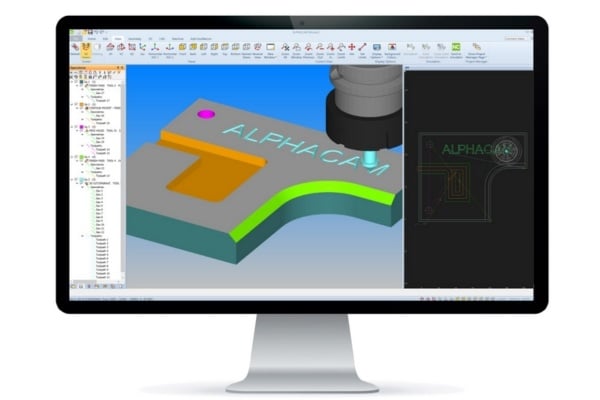

ALPHACAM can automate sending your job to your CNC machinery.

Simply use the out-of-the-box ALPHACAM export with pre-installed layer set available in the Leica iCON trades software.

ALPHACAM does the rest automatically using the

'Leica iCON' macro.

We're with you every step of the way

Our specialist construction team work alongside our customers as technical partners, able to provide in-depth advice, training and ongoing support. Reach out to us for more information on any of our solutions and advice on overcoming technical challenges.

Lawrence Lewis

North Island

North Island

South Island